MUNICH - Industrial investment group Adcuram acquired a controlling stake - 98.57 percent - in luxury kitchen cabinet manufacturer Poggenpohl.

A leading brand for luxury kitchens and known in particular for its Porsche-Design products, Poggenpohl has 70 kitchen design studios worldwide. The company generates annual revenues of c.110 million Euro and employs around 500 staff. The origins of Poggenpohl date back to 1892 when the company was founded as Germany’s first kitchen brand. Since 2000 Poggenpohl has been majority-owned by Swedish listed corporate Nobia AB.

Although its first US dealer was authorized in 1970, it wasn't until 1986 that its first US subsidiary - Poggenpohl USA - was established in Allandale, New Jersey.

Although its first US dealer was authorized in 1970, it wasn't until 1986 that its first US subsidiary - Poggenpohl USA - was established in Allandale, New Jersey.

Over the past few years the U.S. market has become increasing attractive for German cabinet firms. U.S. investors CoBe Capital acquired Warendorfer Küchen, a maker of premium kitchen cabinetry from AFG Arbonia-Forster-Holding AG in 2012.

"With Poggenpohl, we acquire one of the globally leading manufacturers of luxury kitchens. We look forward to... continuing the success story of this extraordinary and iconic brand,” said Thomas Probst, Adcuram board member.

Adcuram said its plans for the business include investments into Poggenpohl’s brand positioning, expansion of the product portfolio, support for retail partners and Poggenpohl operated stores, and optimization of the production process.

“We are pleased to have an experienced and renowned investor by our side in the form of Adcuram Group AG," said Patrick Heinen, managing director of Poggenpohl. "Together we want to further develop the brand Poggenpohl and to accelerate the growth of our business.”

The transaction with the previous majority shareholder, Swedish listed Nobia AB, was recently signed and still subject to regulatory approval.

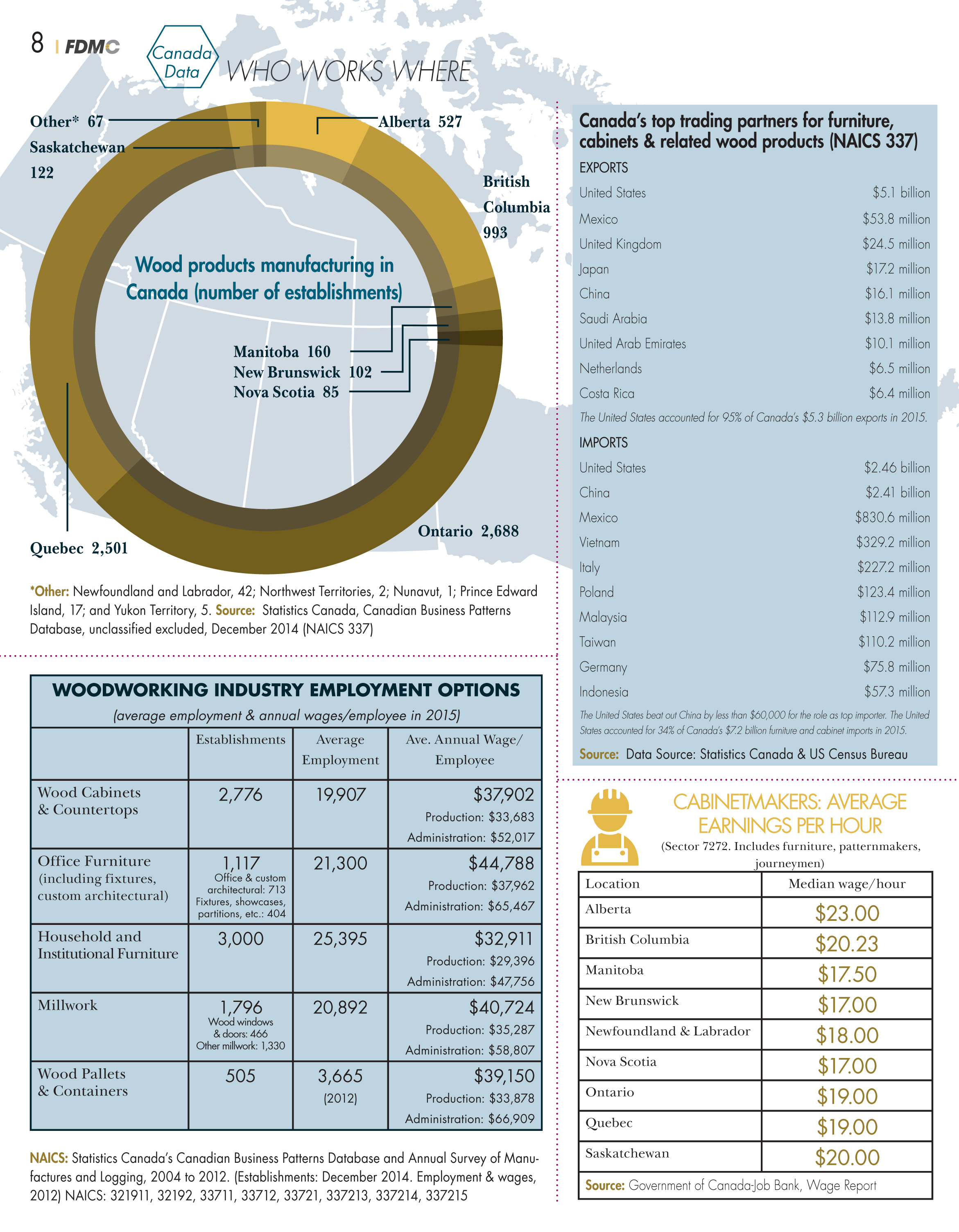

Highlighted in the infographics are the top Canadian provinces for wood products manufacturing, average annual wages per industry, average hourly earnings for cabinetmakers by region, and a listing of Canada's top trading partners.

(Click on the image to enlarge.)

BARTOW, Fla. - Ideal Cabinetry will be displaying WeatherStrong outdoor cabinetry at the International Builders Show in Orlando, January 10-12, 2017.

Ideal Cabinetry has introduced a new modular outdoor cabinetry program under the brand name WeatherStrong. The cabinets are manufactured to order in Bartow from a marine grade waterproof polymer and feature 304 grade stainless steel hardware. Built from a 3⁄4-inch thick marine grade PVC polymer with precision dowel alignment and a fast-cure, solvent-free structural adhesive system, the durable outdoor cabinets are offered in four door styles and ship in 7-10 business days.

The outdoor cabinets are available in a broad range of sizes and options. These include open back cabinets designed to be installed against a wall, island base cabinets, designed to be freestanding, and bar back cabinets that feature a 6-inch high raised back section designed to support a bar counter.

The company also makes the All Wood Cabinetry line of semi-custom factory-assembled kitchen and bath cabinets, featuring all-plywood construction, soft close door inges and soft close dovetail drawers. Euro RTA is a system of ready-to-assemble kitchen and bath cabinets, in 40 styles and finishes, inspired by the clean contemporary lines of European furniture. Technik Cabinetry System is a fully assembled modular closet and storage system, built to order from ¾-inch thick furniture grade particleboard with a durable melamine laminate finish. For more information see www.idealcabinetry.com.

ALFRED, Ontario– A robotic automated lean panel processing center was demonstrated recently at Muskoka Cabinet Co. The eastern Ontario cabinet manufacturer hosted an open house event showing a robotic system by AutomaTech Robotik that could process 80 to 100 cabinets per shift with no programming and only one operator required.

AutomaTech Robotik wanted to demonstrate the efficiency of the robotic Ernest cell that has been integrated at Muskoka. AutomaTech also wanted to promote the Smart tracking RFID system and the SMART Cart (AGV cart), according to Tommy Gagnon of AutomaTech Robotik

The robotic system and the RFID tracking system were demonstrated at the event. The AGV system will be demonstrate in January in another open house.

At Muskoka, the system reportedly can be set up with existing equipment automation, can be done with seamless integration and RFID production tracking.

Gagnon said the robotic processing center at Muskoka Cabinet integrates the complete machining process from cutting to storage and retrieval system with their smart cart. The Robot loads and unloads the CNC routers and the horizontal boring machine. It puts the part on an exit conveyor where the part is label with a RFID tag and goes to the edgebander operator, who is the operator of the complete cell

Equipment used in the processing center includes Homag BOF, Homag edgebander, Omal dowel inserter. AutomaTech technology combines with a Kuka robot. For more information, contact AutomaTech Robotik in St. Appollinaire, Quebec, at http://automatechrobotik.com. Also see www.woodworkingrobot.com.

WINCHESTER, Va. – Kitchen and bath cabinetry giant American Woodmark Corp. said it will invest $30 million to build a new headquarters in Winchester, Virginia, consolidating operations currently held in four locations. Completion of the project is expected to be in early 2018 and will add 55 jobs to the area.

"By bringing our employees together at one location, we will further strengthen our interpersonal connections, drive efficiency in our day-to-day interactions and greatly enhance our ability to move our culture towards our vision," said President and CEO Cary Dunston.

American Woodmark worked with the Virginia Economic Development Partnership and Frederick County, and Governor Terry McAuliffe approved a $550,000 grant from the Commonwealth's Opportunity Fund to assist the county with the project. A $350,000 local economic development grant was also approved by Frederick County. Funding and services to support the company’s employee training activities will be provided through the Virginia Jobs Investment Program.

“Ensuring companies like American Woodmark Corporation, that are central to the economic strength of a region, have the resources and support to thrive is a top priority for my administration,” said Governor McAuliffe. “I congratulate American Woodmark on their headquarters consolidation and commend their decision to stay in Frederick County, retaining 377 valuable jobs and adding 55 more. The company’s success is a testament to the skilled labor and strong business climate of the region, and we will continue to invest in advanced manufacturing, as it is central to diversifying and building a new Virginia economy.”

The cabinet manufacturer simultaneously announced the repurchase of up to $50 million of the company's outstanding common shares. The authorization by the board of directors is in addition to the $15 million remaining from a November 2014 authorization and $1.5 million remaining from the November 2015 authorization. Management expects to fund share repurchases using available cash and cash generated from operations.

American Woodmark markets its cabinetry under the American Woodmark, Shenandoah, Timberlake and Waypoint brands. It currently has nine manufacturing facilities and seven service centers located nationwide. Used in new home construction and remodeling, the kitchen cabinets and bathroom vanities are sold on a national basis directly to home centers, major builders and through a network of independent distributors.

Net sales for the first six months of the current fiscal year were $522.2 million. Net sales for the fiscal year ending April 30, 2016, were $947.0 million.

ALEXANDER CITY, Ala. -- Wellborn Forest Products has announced the appointment of Tim Wellborn as president and CEO. Having served as Wellborn Forest Products president and CEO from 1996-2008, Tim will be leading with a new strategic vision while renewing the foundation and legacy that the cabinet company was built upon. Tim will advance the high-end semi-custom cabinet operation’s growth and profitability with an emphasis on craftsmanship through product innovation and technology reinvestment.

Tim’s father, Doug Wellborn and his brother, Paul Wellborn, founded Wellborn Cabinet Co. in 1963. Tim served as vice president of sales for Wellborn Cabinet Co. from 1980-1987 at which point Wellborn Forest Products was established in Alexander City.

The company produced low-end price-point cabinetry for the multi-unit housing industry. As the company grew, Tim and his father Doug began to move towards higher-end semi-custom cabinetry which is still being produced today.

Tim served as vice president of sales at Wellborn Forest Products from 1987 to 1996, after which he became the company’s President and CEO. Tim has continuously contributed time and expertise not only leading Wellborn Forest Products but also serving on the board of directors of the Kitchen Cabinet Manufacturing Association for more than seven years. Tim’s wife, Pam, who had served as director of design and color until 2008, will continue to influence the company’s product design and finish options. For more information see http://www.wellbornforest.com.

NEWS Tim Wellborn returns to the helm at Wellborn Forest Products Wellborn Forest Products named Tim Wellborn as president and CEO, a position he also held from 1996-2008. |  |

Sold as the Floating Island Base, Peninsula Floating Island Base, Chopping Block Table; freestanding base, vanity and tall cabinets with a Void Toe Kick option, masco says the recalled cabinets pose a potential tip-over hazard when the drawers or roll-out trays are extended. It is offering a repair kit, or full or partial refunds. Masco Cabinetry for a repair kit containing parts and instructions for how to modify the product for safe use, or a full or partial refund.

East Earl, Pa. – Conestoga Wood Specialties recently completed a 47,000-square-foot addition to its East Earl, Pennsylvania, facility to consolidate and expand its finishing operation and streamline capabilities. The cabinet components manufacturer cited consistent market growth and a rising demand for painted kitchens among the reasons for the expansion.

“Demand for paint continues to rise market wide," said Conestoga CEO Anthony Hahn. "We’ve been doing the math all along, knowing we had to grow our capacity to stay ahead of the curve. We have the best track record for quality and on-time delivery in the industry, and we intend to keep it that way.

According to the company, for the past five years its painted finish volume has averaged more than 20 percent year over year growth – more than doubling its daily piece volume. Research by a cross-functional team at Conestoga led to the decision to purchase a Venjakob finishing system from Stiles Machinery, which would handle priming, painting, and topcoating capabilities.

The expansion took six months to complete. The completed finishing facility includes:

• a Venjakob automatic flatline finishing system which applies and dries coatings on the various wood components;

• a freestanding spray booth with a downdraft feature, for use when manual application is necessary;

• a freestanding infrared oven with state-of-the-art with programmable heating for products coated in the off-line spray booth;

• and sanding rooms with downdraft tables that include self-contained filtration systems to remove particulate dust from the hand sanding area, and returning clean air to the room.

Following completion of the expansion, Conestoga said it has experienced a 200 percent increase in finishing efficiency.

“The improved repeatability, shorter cycle times, and significantly larger workspace have provided us with the long-term growth solution we were shooting for," said Jason Earhart, Conestoga finishing technical manager.

Hahn added, “This expansion has significantly increased our finishing capabilities, enabling Conestoga to meet our customers’ demands for the highest quality finishes and on-time delivery they’ve come to expect for many years to come.”

Conestoga Wood Specialties’ commitment to quality, service and product innovation is a driving force in the cabinet components manufacturer’s success.

Conestoga Wood Specialties’ commitment to quality, service and product innovation is a driving force in the cabinet components manufacturer’s success.

“Everything we do is custom,” said Jeff Eichenseer, director of Marketing & Product Development. “If you tell us what you want we can generally do it.”

And do it fast. Standard turnaround on unfinished projects is 10 days, with a practically perfect (99.875 percent) on-time delivery rate.

It’s capabilities like these that keep the family-owned firm one of largest producers in the marketplace. Founded in 1964 and based in East Earl, Pennsylvania, Conestoga has approximately 1,200 employees and 953,057 square feet of manufacturing space spread across five locations. 2016 sales are estimated at more than $140 million.

The East Earl plant is the largest, boasting 449,966 square feet of production space. Targeted for the custom kitchen segment, the primary products include cabinet doors, drawer fronts, front frames and mouldings, made with solid wood, MDF and thermally structured surfaces (TSS).

The new Strata and Argos lines of TSS products are offered in more than two dozen colors and multiple textures, including linear grain patterns and registered-embossed patterns that match the board’s grain patterns. Customer response to the TSS line has been overwhelmingly positive, Eichenseer said, and equipment has been added to keep up with demand.

Edging the competition

At the East Earl location, along with new Holzma HPP panel saws for cutting the large panels to size, Conestoga acquired a new Brandt edgebander with the dual purpose of applying both PUR and hot air edgebanding.

With the growing popularity for Strata, the Brandt has already become a workhorse at the plant. In the PUR mode, it applies banding to an average of 400 cabinet doors per shift, or the equivalent of 1,600 passes. “It’s capable of handling orders of just about any panel size,” Eichenseer said.

The hot air capability also will be critical when the company ramps up production on a new line of high gloss components, set to debut first quarter of 2017.

How a hot air edgebander works is a stream of hot, compressed air is forced through a slot nozzle and directed onto a reactive layer of specialized edgeband, activating the adhesive so the banding bonds to the panel edge. Benefits include the ability to produce a seamless edge, which can be critical with a high gloss finish.

The machine can be changed over to hot air “at the switch of a button,” said Daryl Cromwell, production manager. “The operators will be trained on both methods, and can flip back and forth as needed.”

High-tech finishing expansion

As it branches into textured and glossy finishes, Conestoga has not forgotten its roots. The company recently expanded and consolidated its finishing operation to meet the growing demand for painted wood kitchens.

Over the past five years, Conestoga’s painted finish volume has averaged more than 20 percent year over year growth. “We’ve been doing the math all along, knowing we had to grow our capacity to stay ahead of the curve,” said CEO Anthony Hahn. “This expansion has significantly increased our finishing capabilities, enabling Conestoga to meet our customers’ demands for the highest quality finishes and on-time delivery they’ve come to expect, for many years to come.”

Watch a time-lapse video of showing the construction and installation of the new finishing area.

The new 47,000-square-foot facility houses a state-of-the-art Venjakob automatic flatline UV finishing system for applying and drying coatings. Unique on the line is a “smart” material handling system that places parts on specified racks for staging before they’re dried in the UV oven, Eichenseer explained.

Conestoga Wood Specialties completes 47,000-square-foot finishing expansion The cabinet components manufacturer recently completed a 47,000-square-foot addition to its East Earl, Pennsylvania, facility to consolidate and expand its finishing operation and streamline capabilities. Also watch the time-lapse video of the construction and installation. |  |

Also in the building are a freestanding spray booth and infrared oven for manual applications, and sanding rooms with Denray downdraft tables.

“The improved repeatability, shorter cycle times, and significantly larger workspace have provided us with the long-term growth solution we were shooting for,” said Jason Earhart, Finishing technical manager.

Added Hahn, “This expansion has significantly increased our finishing capabilities, enabling Conestoga to meet our customers’ demands for the highest quality finishes and on-time delivery they’ve come to expect for many years to come.”

An on-site finishing lab enables Conestoga to custom color match in addition to its thousands of paint, stain and glaze offerings. Becker and Sherwin Williams finishing materials are used in the shop.

Sustainable manufacturing

Sustainable manufacturing

A sustainable manufacturer, Conestoga has been certified under the Kitchen Cabinet Manufacturers Association (KCMA) Environmental Stewardship Program since 2008, and is a past winner of the Pennsylvania Governor’s Award for Environmental Excellence.

From start to finish, Conestoga puts a priority on quality and service, and its tagline of “absolute dependability” reflects this. At East Earl, for example, the company has an on-site deconstructive lab and climate chamber for testing glue joints and more on the components, while within the workcells checks for internal and external defects are conducted on a continuous basis, Eichenseer said. This is no mean feat considering more than 800 orders are processed daily.

At East Earl, it starts in the rough mill area, where Weinig CNC moulders machine several thousand feet of moulding each day. “We have literally thousands of profiles,” Eichenseer said. An on-site tooling department manufactures and maintains the carbide and high-speed steel cutting tools for the plant; diamond tooling is outsourced.

Other equipment at East Earl includes: saws equipped with TigerStop cutting automation, Routech and Thermwood CNC routers, Schmalz vacuum lifters, Accu-Systems boring, mortising and tenoning machines, Unique shape and sand, and a variety of sanders, including Sandingmaster, Timesavers, Costa and QuickWood.

Conestoga combines technology with handcraftsmanship to make its custom doors and drawer fronts, offered in a wide variety of styles including: five-piece, three-piece, slab, miter, mullion, radius, raised panel, recessed panel, mortise and tenon, applied moulding and beaded panel. “If you can draw it, we can figure out how to make it,” Eichenseer said. “There’s very little we won’t do.”

Conestoga combines technology with handcraftsmanship to make its custom doors and drawer fronts, offered in a wide variety of styles including: five-piece, three-piece, slab, miter, mullion, radius, raised panel, recessed panel, mortise and tenon, applied moulding and beaded panel. “If you can draw it, we can figure out how to make it,” Eichenseer said. “There’s very little we won’t do.”

While more than half the products sold are of solid wood, hybrids – a combination of solid wood and MDF – are growing in popularity and now account for almost a third of sales. “We’re also seeing surge for MDF and painted products,” Eichenseer added.

In addition to production in East Earl, Conestoga operates four other plants. The 139,225-square-foot facility in Kenly, North Carolina, services the custom kitchen market, producing RTA cabinetry, dovetail drawer boxes and edgebanded slab products. Components for the OEM segment, including solid wood, MDF and plywood doors and drawer fronts, are made at the 71,521-square-foot Beaver Springs, Pennsylvania facility.

Dimension stock and glued up panels for the three facilities are supplied by Conestoga’s 243,545-square-foot dimension mill, located in Beavertown, Pennsylvania. The Beavertown plant also supplies cut-to-size plywood and MDF panels to the Beaver Springs facility.

And at its 48,800-square-foot location in Seattle, Washington, Conestoga produces doors, drawer fronts and dovetail drawers, as well as the Argos line of TSS cabinet components for custom kitchen manufacturers.

As an added service, Conestoga will supply specialty products, including legs and corbels, to coordinate with its cabinet components. “We don’t machine these products ourselves because we want to remain focused on what we do best,” while providing a one-stop shopping service to customers, Eichenseer said.

TORONTO -- AyA Kitchens, in collaboration with award-winning design firm Partisans, will be unveiling CUBI at the upcoming Interior Design Show. CUBI is described as the art of flexibility. Conceived as a versatile, sculptural series of cubic geometries, the multi-purpose units can be used as storage, walls, benches, cooking and dining surfaces as well as trusses for light fixtures and even planting. The CUBI design offers mass customization. Creative yet practical, whimsical yet individualized, no one CUBI scheme is alike. Each offers the same flexibility required to meet the challenges of the tightest of spaces or most open of concepts.

The Interior Design Show will be held January 19 to 22 in Toronto.

Partisans has also been involved in AM Station, a permanent installation comprised of a shippable architecture that will accommodate the exhibition of art and architecture books, multiples, comics, zines, and films, as well as lectures, pop-up shops, and art and art book fairs. in Union Station in Toronto. For more information on AyA Kitchens, see http://Ayakitchens.com.

MINNEAPOLIS, Minn. - Kitchen cabinet provider CliqStudios has announced plans to invest nearly $2 million in a new design studio in St. Louis County, Missouri. The Minnesota-based company, reportedly the largest U.S. online seller of semi-custom cabinets through its website CliqStudios.com, says the new location will help create 98 jobs.

This latest expansion will help the cabinetry firm accommodate its growing customer base, according to CliqStudios. The company announced in November it would invest $5.1 million to build a design studio in Indianapolis, Indiana.

“CliqStudios selected Indianapolis and St. Louis as the sites for our expanded design studios because of the excellent availability of outstanding design talent in each market,” said Joy Schmelzer, vice president of Customer Experience at CliqStudios.com. “We expect to create up to 200 jobs in both new design studios over the next five years.”

The Missouri Department of Economic Development has offered a strategic incentive package that the company can receive if it meets strict job creation criteria.

“This is great news for the St. Louis region and another concrete example of the economic progress we’re seeing all across our state,” said Missouri Gov. Jay Nixon. “I thank CliqStudios for investing and creating jobs in our state, and look forward to seeing them continue to grow and succeed here in the heartland.”

The St. Louis expansion brings to five the number of cabinet design studios CliqStudios has located throughout the Midwest, including its 1.8 million-square-foot factory in Connersville, Indiana, which opened in 2014. CliqStudios is a unit of Wayzata Home Products and said it projects its growth to continue throughout 2017 and beyond.

CliqStudios names Tiller new CEO

In related news, the CliqStudios Board of Directors has appointed Tom Tiller as CEO. The company, which made the announcement Jan. 5, said the appointment is effective immediately. Founder and former CEO Andy Juang will remain with the company as Chairman of the Board.

Tiller will be based at the company's new headquarter location in Bloomington, Minnesota. He has a BSME from MIT and a MBA from Harvard Business School. Prior to joining CliqStudios, Tiller worked at General Electric in GE Aerospace as a design engineer and progressed through a variety of management roles there. He also served in senior roles at GE Appliances and GE Silicones and was the CEO of Polaris Industries and later at Abound Solar. He has served on the advisory board of CliqStudios for the past three years.

“Since its founding in 2010, Andy and the entire Cliq team have come a very long way," Tiller said. "CliqStudios has quickly become the market leader for high quality, on-line kitchen cabinets."

"We look forward to growing the company and to continue to help customers remodel their kitchens in a fundamentally better way – easier, faster, and with better value than traditional options. I am very excited to be a part of this rapidly growing company.”

In addition to Tiller's hiring, Boston-based private equity firm Great Hill Partners recently made a strategic investment in the company. Related investments by Great Hill include e-commerce firms Wayfair and The Shade Store.

ANN ARBOR, Mich. -- Merillat Cabinetry is introducing new Merillat Classic door styles, along with new accent and finish options for 2017. These new products, available in showrooms starting February 20, include new finishes and new designs.

The new 2017 Merillat Classic line will include: Two new door styles, including the Lanielle textured laminate in Whisper and Cavern finishes; Six new glaze options; Sable stain is now available in oak; and two new gray paint colors.

“We focused our new line on expanding finish options and creating cabinets with a very high-end look that are durable enough for everyday use,” said Jessica Joffe, director of product management, Merillat Cabinetry.

Merillat Cabinetry’s team will offer information about their new product line January 10-12, 2017 at The Kitchen & Bath Show in Orlando, Florida. Merillat Cabinetry representatives will be available for meetings and conversations about improvements to their latest products with show attendees. For more information see www.merillat.com.

ASHLAND, Ala. -- Wellborn Cabinet Inc. is introducing a new modern design at KBIS 2017. The Aspire Cabinetry features clean lines, crisp edges, and coordinating colors to provide a modern look.

Aspire Cabinetry is the new full access frameless line by Wellborn Cabinet set to launch in the first quarter of 2017. Aspire Cabinetry is intended to add the finishing touches to a large group of new designs currently available with Wellborn Cabinet.

This modernistic line has parallels in design between the top upper cabinets and the wooden section of the peninsula, each cascading from top to bottom.

One color or material in the design is not allowed to dominate the other. The continuous line across the top of the cabinetry corresponds with the stainless-steel bar running laterally along the way.

With the entire kitchen outfitted with the touch-to-open technology and deep storage pullout drawers to provide ample storage, this kitchen was designed for the chef in mind. The Midtown Gloss Marine provides a polished tone to the soft Arcadia Cotton Pine while the Midtown Matte Graphite grounds the design. See http://www.wellborn.com.